路沿石模具在凹模的设计中,采用镶拼结构的好处有在路沿石模具的生产设计中,简化凹模型腔加工,将复杂的凹模内形体的加工变成镶件的外形加工,降低了凹模整体的加工难度。

In the design of die for curbstone, the advantage of using inlay structure is that in the production design of curb stone mold, the processing of cavity of concave mold is simplified, and the processing of complex internal body of concave mold is turned into the shape processing of insert, which reduces the processing difficulty of the whole die.

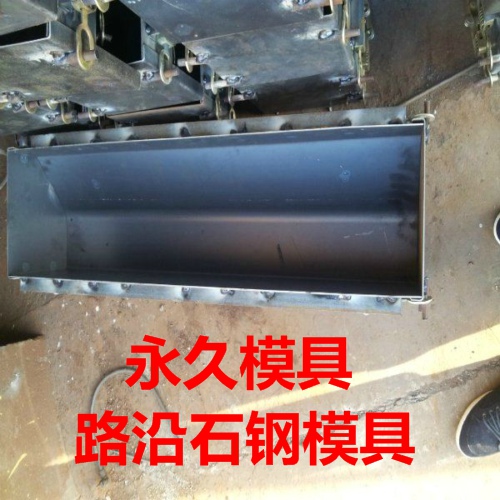

路沿石模具镶件可用高碳钢或高碳合金钢淬火后变形小。可用专用磨床复杂形状和曲面。凹模中使用镶件的局部型腔有较高精度。经久的耐磨性并可置换。可节约****塑料模具钢,尤其对于路沿石模具更是如此;有利于排气系统和冷却系统的通道设计和加工。

High carbon steel or high carbon alloy steel can be used for the insert of curbstone mould, and the deformation is small after quenching. Special grinding machines are available for complex shapes and curved surfaces. The local cavity with insert in the female die has higher precision. Durable wear resistance and replaceable. It can save high-quality plastic mould steel, especially for curbstone mould, and is conducive to the design and processing of exhaust system and cooling system.

路沿石模具结构设计中还应注意以下要点:凹模的强度和刚度因此有所削弱,故模框板应有足够的强度和刚度;镶件之间、镶件与模框之间应尽量采用凹凸模相互扣锁,以减小整体凹模在高压下的变形和镶件的位移。镶件必须****定位,并有可靠紧固;镶件解封必须配合紧密,转角和曲面去不能设置拼缝,拼缝线方向应与脱模方向一致。

The following points should also be paid attention to in the structural design of curb stone mould: the strength and rigidity of female die are weakened, so the die frame plate should have enough strength and rigidity; the concave convex die should be used to lock each other between the inserts and between the inserts and the mold frame, so as to reduce the deformation of the whole die and the displacement of the insert under high pressure. The insert must be accurately positioned and reliably fastened; the unsealing of the insert must be closely matched; the edge seam cannot be set at the corner and curved surface, and the direction of the seam line should be consistent with the demoulding direction

路沿石模具制作模具此阶段主要是客户与供应商之间进行的关于产品设计和模具开发等方面的技术探讨,主要的目的是为了让供应商清楚地领会到产品设计者的设计意图及精度要求,同时也让产品设计者更好地明白模具生产的能力,产品的工艺性能,从而做出更合理的设计。

The main purpose of this stage is to let the supplier clearly understand the design intention and precision requirements of the product designer, and also let the product designer better understand the mold production capacity and product process performance, so as to make the product more suitable Rational design.